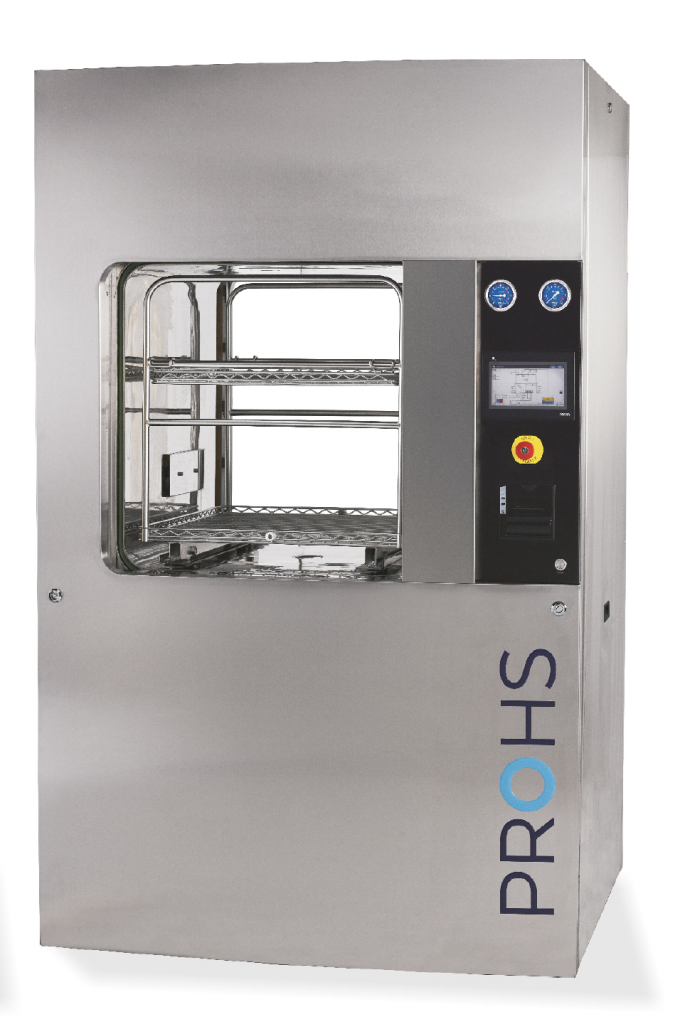

PROHS vertical steam sterilizer has as its base function, the complete elimination of all living microorganisms, controlling temperature, pressure and time.

Through a fast and uniform heat transference, PROHS vertical steam sterilizers were specifically designed for laboratory use.

Technical Characteristics

– Chamber and lid built in AISI 316L stainless steel.

– External structure in AISI 304 stainless steel.

– Manual top lid, hermetically closed by knobs and silicon gasket.

– The entire control is made through the PLC (Programmable Logic Controller).

– 3.5″ color touch screen providing an easy and intuitive interface

– The heating is performed by electrical heaters.

– Drying is performed through vacuum caused by thermal shock over the entire height of the chamber, thus achieving a quick and effective drying.

– As an option, drying can be performed by a vacuum pump.

– A thermostatic steam trap is used to achieve automatic elimination of the steam condensates inside the chamber.

CONSTRUCTION

Chamber and cover built from AISI 316L stainless steel highly resistant to corrosion. The rest of the outer structure is made from AISI 304 stainless steel.

DRYING

Vacuum drying by means of thermal shock throughout the whole of the chamber, leading to quick and effective drying.

CYCLES

The sterilizer allows the user to program the standard sterilization cycles according to different temperature and time.

The sterilizer is pre-configured with 8 programs for Solid and Liquid loads. However, it can be configured with up to 20 totally customizable programs according to your needs.

For Liquid cycles it can be controlled by the chamber temperature sensor or by a flexible sensor directly applied in the product.

Control by time or by FO.

External Connections

Power Supply: 3~400V / 50Hz

– Water: 1/2″- 1 to 6 Bar (x101Pa)

– Sewer: 3/4″ – Temperature resistant material